For more information please feel free to contact us and one of our advisors will be available to help.

Office Opening Hours: 9:00AM – 17:00PM Monday – Friday

Please leave us an email if out of hours.

Our electrical engineering team at Smart CI Group recently reached an important milestone with the delivery of a fully integrated curing chamber heating system for a leading UK building materials manufacturer.

This complex industrial project showcased our ability to combine precision electrical engineering, in-house fabrication, and custom installation across multiple high-performance systems, all designed to optimise production efficiency and thermal control.

The client required a reliable, high-efficiency heating solution for two large curing chambers within their production facility. These chambers needed to maintain consistent temperature and airflow levels to ensure even curing and product quality - a technically demanding environment with limited access and tight project timelines.

Our teams were responsible for designing, installing, and commissioning the entire heating and control system, including pipework, electric boilers, and monitoring equipment.

Working collaboratively across divisions, Smart CI Group delivered a complete turnkey installation, combining electrical, mechanical, and fabrication expertise.

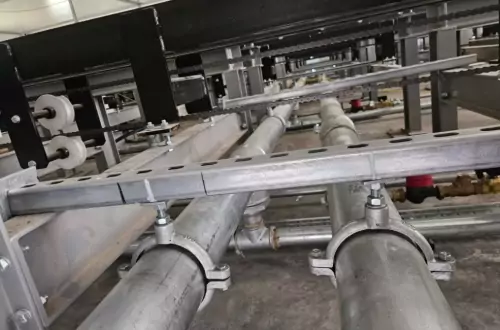

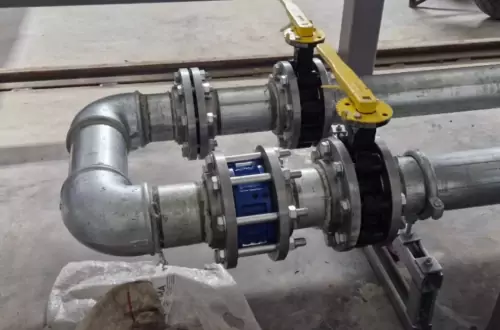

We installed a custom 100mm feed and return pipe system inside a circular curing chamber, using segmented lengths and flexible joints to ensure precision fitting. The system feeds 19 individual heat exchangers, providing accurate and even temperature control throughout.

A similar installation was completed in the Matrix Chamber - this time within a grid layout featuring a dedicated preheat chamber for consistent airflow and temperature balance.

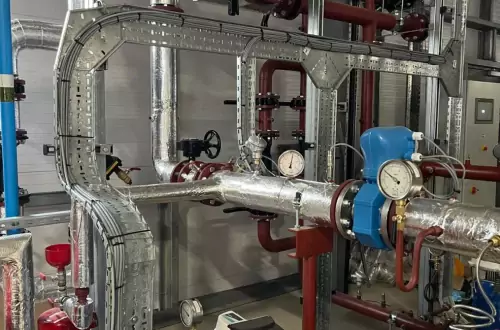

Both chambers were equipped with high-efficiency electric boilers, fully monitored through HMI panels displaying real-time data on flow, pressure, and temperature.

To enhance energy performance, our team provided comprehensive lagging across all pipework, minimising heat loss. Much of the system’s framework and fittings were fabricated in-house at our Sittingbourne workshop, ensuring precision and rapid turnaround.

Following the success of this installation, we’ve continued supporting the client on further site developments, including a new tile factory where our engineers are installing containment and cabling for control wiring on the production line.

This includes:

Supplying and installing CY cabling on heavy-duty tray-mounted side profiles (300–450mm)

Fabricating 50x 100x100 box-section posts with foot plates and anchor bolts for structural stability and cable support

This project exemplifies Smart CI Group’s multi-disciplinary engineering capability - combining electrical precision, fabrication skill, and collaborative problem-solving to deliver reliable, efficient, and safe industrial systems.

The success of the curing chamber installation has strengthened our long-term partnership with this major UK manufacturer and further highlighted our expertise in custom-built electrical and mechanical solutions for complex industrial environments.

For more information please feel free to contact us and one of our advisors will be available to help.

Office Opening Hours: 9:00AM – 17:00PM Monday – Friday

Please leave us an email if out of hours.

How can we help?